In the modern electronics manufacturing industry, device programming has become a critical process that directly impacts production efficiency, product quality, and time-to-market. As embedded systems and smart devices continue to proliferate across automotive, consumer electronics, industrial automation, and medical equipment sectors, the choice of programming methodology has emerged as a strategic decision that can significantly influence manufacturing economics and operational flexibility.

The evolution of programmable devices from early EEPROM-based microcontrollers to modern flash-memory-enabled systems has fundamentally transformed how firmware is loaded into devices. This technological advancement, pioneered by companies like Atmel who developed the first microcontroller with flash memory in the early 1990s, enabled more efficient program execution and data storage while dramatically simplifying the programming process compared to previous technologies. Flash memory's advantages—including reprogrammability, lower read latency, high endurance for write cycles, and durability in harsh environments—have made it the standard for modern embedded systems.

Key Insight: Understanding the distinction between ISP and Offline Programming requires examining not only their technical implementation but also their broader implications for production planning, quality control, supply chain management, and total cost of ownership.

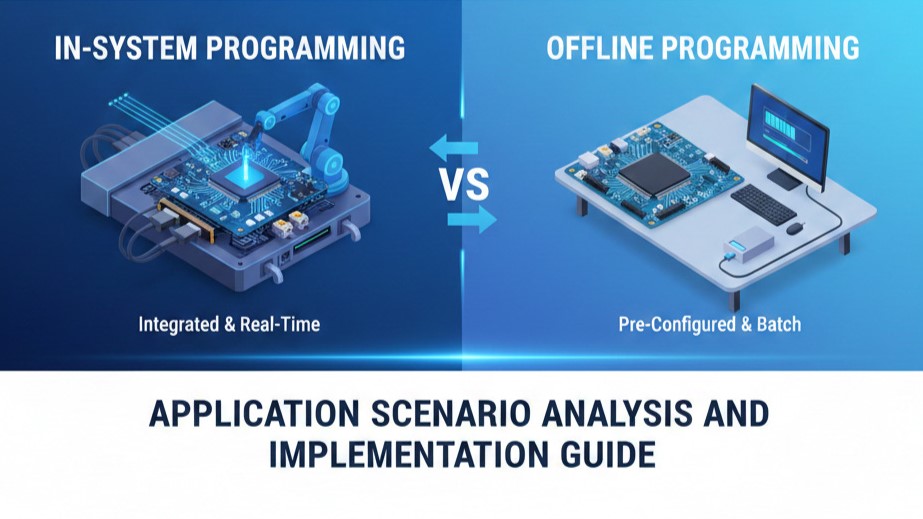

This comprehensive guide examines two primary approaches to device programming: In-System Programming (ISP) and Offline Programming, analyzing their technical characteristics, application scenarios, advantages and disadvantages, and providing practical implementation guidance to help manufacturers make informed decisions aligned with their specific production requirements.

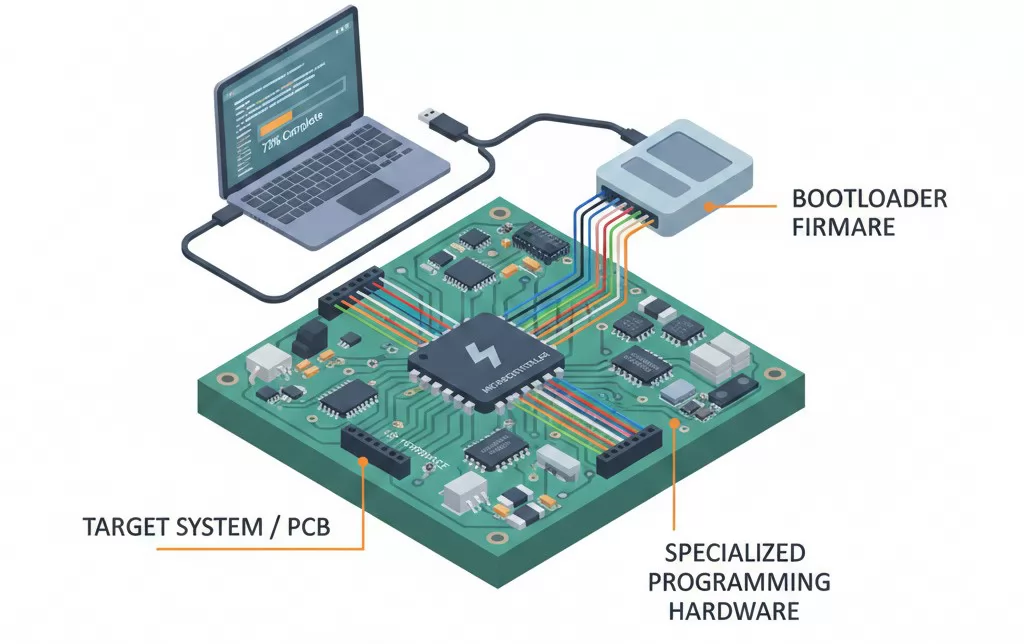

In-System Programming, also referred to as In-Circuit Serial Programming (ICSP), represents a programming methodology that enables the programming or reprogramming of programmable logic devices, microcontrollers, and chipsets while they remain installed within their target system or circuit board. This approach eliminates the traditional requirement of programming devices prior to assembly, instead integrating the programming process directly into the manufacturing or field service workflow.

The technical implementation of ISP relies on specialized programming hardware that establishes communication with the target device through designated programming pins accessible on the assembled PCB. These programming interfaces must be considered during the initial circuit design phase to ensure proper pin access and electrical compatibility. Modern microcontrollers typically incorporate bootloader firmware that facilitates the ISP process, enabling the device to receive and write program data to designated areas of its internal flash memory.

Devices can be programmed directly on the assembly line while integrated into the target system

Manufacturers can respond quickly to changes in programming requirements

Firmware modifications possible without removing the device from its environment

Programming can only be performed when the target chip supports ISP functionality and the circuit board has been designed with proper pin access for programming connections.

ISP utilizes serial data transmission, transferring program data bits sequentially rather than simultaneously. For large firmware images, this can result in longer programming times.

Concurrent programming capabilities are limited by the physical constraints of the PCB panel size and the number of available ISP programmer channels.

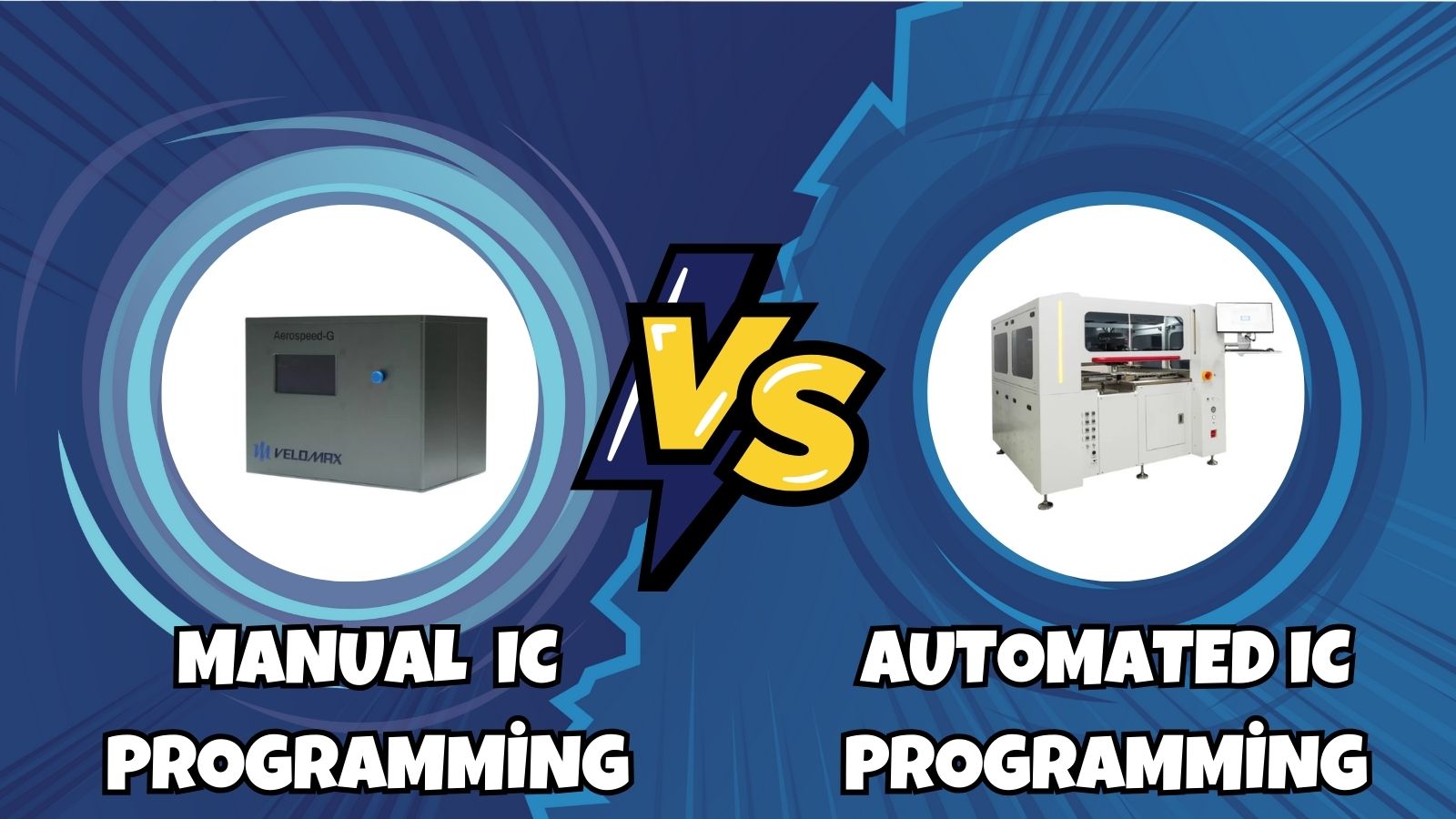

Offline Programming, also known as in-socket programming or parallel programming, refers to a methodology where devices are programmed prior to their assembly into the final product, typically using specialized programming equipment that accepts devices directly into socket adapters. This approach separates the programming process from the manufacturing assembly line, establishing an independent production operation focused exclusively on device programming.

The technical implementation of offline programming relies on socket-based programming systems that provide electrical connection between the programming equipment and the device under programming. These socket adapters are designed to accommodate specific device packages and pin configurations, enabling reliable electrical communication for data transfer and verification operations. Modern automated offline programmers support multiple socket positions simultaneously, enabling parallel programming of numerous devices and significantly increasing throughput compared to sequential programming methods.

Parallel data transmission enables significantly faster programming compared to serial ISP methods

Advanced systems support simultaneous programming of 32 or more devices

Supports virtually any socketable device regardless of ISP capability

Switch between device types within minutes using appropriate socket adapters

Automated systems capable of high-volume concurrent programming require substantial capital expenditure

Each device type requires specific socket adapters that undergo wear and require periodic replacement

Firmware issues after assembly require desoldering, reprogramming, and resoldering

The technical performance characteristics of ISP and Offline Programming diverge significantly across multiple dimensions, with each approach offering advantages in specific operational contexts. Programming speed represents the most pronounced difference between these methodologies, with offline programming's parallel interfaces enabling substantially faster data transfer rates compared to ISP's serial communication protocols.

| Performance Factor | In-System Programming | Offline Programming |

|---|---|---|

| Programming Speed | Slower (serial transfer) | Faster (parallel transfer) |

| Max Concurrent Programming | Limited by PCB panel size (up to 16 PCBs) | High concurrency (up to 32+ devices) |

| Throughput | Lower than automated offline systems | Up to 1600 UPH with automated systems |

| Device Compatibility | ISP-supported chips only | Universal (all socketable devices) |

| Changeover Time | May require new fixtures | Minutes with adapter changes |

| Initial Investment | Lower | Higher |

| Rework Complexity | Simple (no desoldering required) | Complex (requires desoldering) |

| Reliability Risk | No mounting risks | Pin deformation possible |

The economic comparison between ISP and Offline Programming requires analysis of multiple cost components including initial capital investment, ongoing operational expenses, and indirect costs associated with production flexibility and quality implications.

Economic Insight: ISP typically requires lower initial capital investment, particularly for manual or semi-automated programming configurations. However, this apparent cost advantage must be weighed against the operating costs associated with production line time allocation and potential throughput limitations.

Offline programming equipment, while requiring higher initial investment, often delivers superior economics at production volumes sufficient to amortize the capital cost and leverage the higher throughput capabilities. The reduced per-unit programming cost achievable with automated parallel programming systems can offset initial investment premiums within reasonable timeframes for manufacturers with consistent high-volume requirements.

Indirect costs including rework expenses, firmware update flexibility, and production responsiveness represent significant economic factors that may favor one approach over another depending on product characteristics and market dynamics. Products with evolving firmware requirements or frequent design updates may incur substantial rework costs with offline programming that could be avoided through ISP's in-circuit update capability.

Preserves solder connection integrity and avoids mechanical stress on device pins that could compromise long-term reliability

Pre-assembly detection of defective devices prevents introduction of faulty components into the assembly process

Quality and reliability considerations vary between ISP and Offline Programming approaches in ways that may be decisive for applications with stringent reliability requirements. ISP's elimination of post-assembly device handling preserves the integrity of solder connections and avoids mechanical stress on device pins that could compromise long-term reliability. For automotive, aerospace, medical, and defense applications where product reliability is mission-critical, this quality advantage may justify the operational trade-offs associated with ISP.

High-volume manufacturing scenarios with stable product designs and established firmware present compelling economics for offline programming approaches. The throughput advantages of parallel programming systems, combined with the ability to pre-program devices before they enter the assembly line, enable efficient production flow and predictable cycle times.

The capital intensity of offline programming equipment is most readily justified in high-volume contexts where throughput capabilities can be fully utilized. Manufacturers producing millions of units annually can achieve favorable return on investment through reduced per-unit programming costs.

Products experiencing frequent firmware updates, evolving specifications, or uncertain demand volumes may not achieve the production volume consistency required to justify offline programming investments.

The scalability of automated offline programming systems enables capacity expansion through equipment additions rather than production line modifications, providing flexibility for demand growth.

High-mix production environments characterized by diverse product variants, moderate volumes, and frequent specification changes present different optimization requirements than high-volume stable production. ISP's flexibility advantages become particularly valuable in these contexts, enabling rapid response to engineering changes, customer-specific configurations, and demand fluctuations.

The ability to update firmware during assembly without stopping production or re-configuring programming equipment provides significant operational advantages in dynamic manufacturing environments.

Products requiring serialization, customer-specific data loading, or configuration flexibility can be efficiently handled through ISP without maintaining separate inventory of pre-programmed variants.

Applications requiring field firmware updates, whether for product improvement, defect correction, or feature enhancement, strongly favor ISP methodology. The ability to update device firmware without physical device removal enables cost-effective field service operations and extends product utility through software enhancements delivered after initial sale.

Connected systems increasingly incorporate remote update capabilities built upon ISP principles, enabling manufacturers to address security vulnerabilities remotely.

Modern vehicles contain dozens of ECUs requiring periodic software updates for emissions compliance, safety issues, and feature enhancements.

Research and development environments present unique programming requirements that typically favor ISP methodology. During development phases, firmware undergoes frequent modification and iteration, often multiple times per day. The flexibility to quickly update device firmware without handling physical components or reconfiguring programming equipment accelerates development cycles and reduces time-to-prototyping.

The lower initial investment requirements of ISP programming equipment also align with research and development budget constraints. Development teams can acquire ISP programming capability with minimal capital investment, redeploying resources to other development priorities.

Selecting between ISP and Offline Programming requires systematic evaluation of multiple factors aligned with organizational capabilities and strategic objectives.

Evaluate production volume and mix complexity. High-volume stable production typically favors offline programming, while high-mix dynamic environments benefit from ISP's flexibility.

Assess the frequency of firmware and design changes. Products with evolving firmware may incur substantial offline programming rework costs.

Evaluate quality and reliability requirements by application domain. High-reliability applications may prefer ISP despite throughput limitations.

Consider capital investment tolerance and risk tolerance for production disruption when evaluating equipment investment decisions.

Determine minimum concurrent programming capacity required to support production volumes without creating bottlenecks.

Ensure selected equipment can program all device types required by the product portfolio to reduce the number of different programmers needed.

Evaluate compatibility with existing manufacturing execution systems, data management infrastructure, and quality systems.

Assess supplier capabilities for support, training, and parts availability to ensure reliable long-term equipment ownership.

The selection between In-System Programming and Offline Programming represents a consequential decision with implications for manufacturing efficiency, product quality, operational flexibility, and total cost of ownership. Neither approach is universally superior; rather, each offers distinct advantages aligned with specific production contexts and organizational requirements.

Key Takeaway: Understanding the technical characteristics, economic factors, and operational trade-offs of each methodology enables informed decision-making that optimizes outcomes for specific circumstances.

In-System Programming excels in scenarios requiring production flexibility, field update capability, and high reliability. Its ability to program devices within their target systems eliminates handling risks, simplifies rework, and enables post-deployment firmware updates. These advantages make ISP particularly suitable for applications with evolving firmware requirements, high reliability demands, or field service needs. The lower initial investment requirements and reduced changeover complexity further favor ISP for high-mix production environments and development-stage manufacturing.

Offline Programming delivers superior throughput and cost efficiency for high-volume stable production where the throughput advantages of parallel programming can be fully leveraged. Its universal device compatibility, high concurrent programming capability, and pre-assembly quality verification provide compelling economics for products with established firmware and sustained production volumes.

Hybrid approaches that utilize both methodologies for different products or production phases can capture benefits from each approach while mitigating their respective limitations. Organizations should evaluate their specific circumstances against the factors outlined in this analysis to develop programming strategies aligned with their operational requirements and strategic objectives. As technology continues to evolve and production requirements change, periodic reassessment of programming methodology selection ensures continued optimization of manufacturing outcomes.

Discover this amazing content and share it with your network!

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.