In the high-stakes world of electronics manufacturing, the IC programmer you choose can make the difference between a streamlined production line and a bottleneck that costs thousands of dollars in lost productivity. Industrial-grade IC programmers are engineered for environments that demand reliability, speed, and scalability—qualities that distinguish them from their laboratory counterparts. This comprehensive guide walks you through the critical considerations that production managers, engineering teams, and procurement specialists must evaluate when investing in industrial programming equipment.

The electronics manufacturing industry has witnessed a remarkable evolution in programming technologies over the past decade. As devices become more complex and production volumes continue to climb, manufacturers face unprecedented challenges in maintaining throughput while ensuring data integrity and device reliability. Modern electronic products increasingly rely on sophisticated memory devices and microcontrollers that require precise programming procedures, making the selection of appropriate programming equipment more critical than ever before.

Industrial-grade IC programmers differ fundamentally from benchtop units designed for development and prototyping environments. While a laboratory programmer might be used intermittently for a handful of devices per day, industrial programmers operate continuously, programming hundreds or thousands of units per shift. This operational difference demands robust hardware construction, sophisticated thermal management, and software architectures optimized for sustained high-throughput performance. The consequences of selecting inappropriate equipment extend beyond mere inconvenience—programming failures in production can result in device damage, yield losses, costly rework, and damaged customer relationships.

Consider this: a programming failure rate of just 0.5% on a production run of 10,000 units translates to 50 defective devices requiring rework or replacement. When factoring in inspection costs, line stoppages, and opportunity costs, the true impact of inadequate programming equipment quickly becomes apparent. Industrial-grade programmers are engineered to minimize these risks through advanced error detection, robust signal integrity, and comprehensive logging capabilities that support root cause analysis and continuous improvement initiatives.

The market for industrial programming solutions encompasses a diverse range of equipment types, from compact single-site programmers suitable for low-volume production to sophisticated automated handling systems capable of processing thousands of units per hour. Understanding where your production requirements fit within this spectrum is essential for making an investment that delivers optimal value throughout its operational lifecycle.

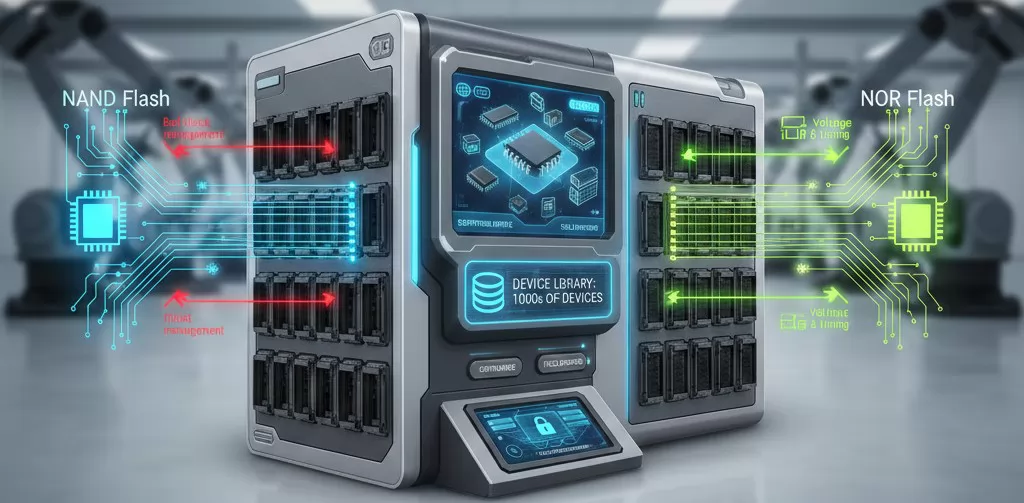

The breadth of device support represents perhaps the most fundamental consideration when evaluating industrial IC programmers. Modern production environments frequently program a diverse array of device types, from traditional EEPROMs and Flash memory to sophisticated microcontrollers, FPGAs, and high-density storage devices like eMMC and UFS. A programmer with limited device support quickly becomes a bottleneck as product designs evolve and new device families enter the production pipeline.

When assessing device support capabilities, look beyond the raw count of supported devices. Examine the manufacturer's track record for adding support for newly released devices, as the semiconductor industry introduces new products regularly. Consider the ease of software updates and whether device support can be extended through field upgrades. Leading industrial programmers maintain extensive device libraries with support for thousands of devices from numerous manufacturers, and they typically offer rapid turnaround times for adding support for newly released chips when requested by customers. The ability to create custom device configurations for specialized or proprietary devices provides additional flexibility for unique production requirements.

The distinction between NAND and NOR flash programming deserves particular attention, as these technologies have fundamentally different programming requirements. NAND flash, commonly used for high-density storage applications, requires sophisticated bad block management algorithms to handle the technology's inherent reliability limitations. NOR flash, favored for code storage applications due to its random access capabilities, demands different voltage and timing parameters. A quality industrial programmer must handle both technologies with appropriate algorithms and verification procedures, including support for the latest multi-level cell (MLC), triple-level cell (TLC), and quad-level cell (QLC) NAND technologies that present increasingly complex programming challenges.

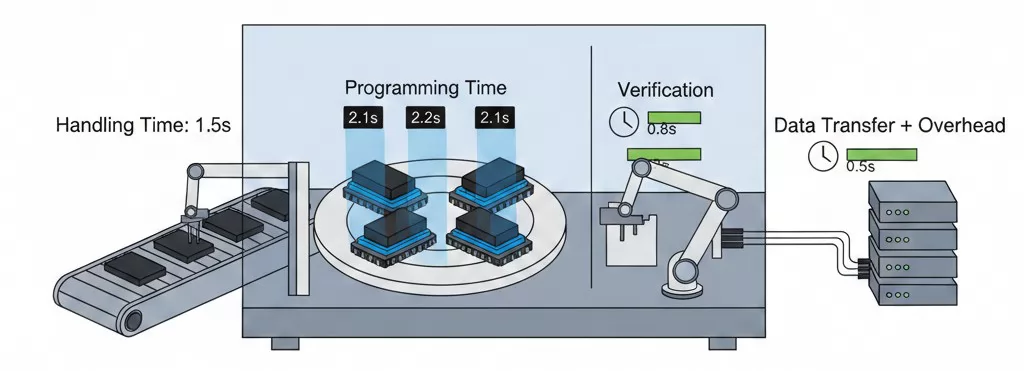

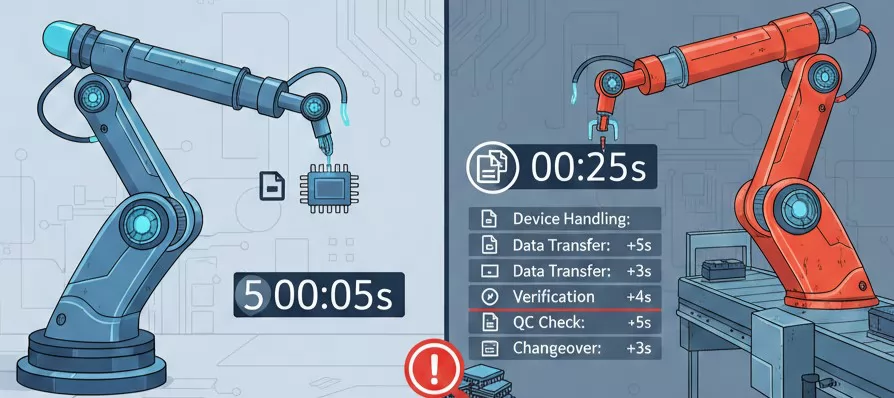

Programming speed specifications require careful interpretation, as advertised figures often represent idealized conditions that differ substantially from real-world production throughput. A programmer claiming "5-second programming time" may achieve this only under optimal conditions with small data files and ideal device characteristics. True production throughput must account for device handling time, socket insertion and extraction cycles, data transfer overhead, and verification procedures that ensure data integrity.

When evaluating throughput specifications, request detailed information about test conditions and consider conducting your own benchmarking with representative devices and data files. Look beyond the raw programming speed to examine the programmer's architecture—systems that support parallel programming of multiple devices can dramatically increase effective throughput. Advanced industrial programmers offer multi-site programming capabilities, enabling simultaneous programming of two, four, or even more devices depending on the system configuration. For high-volume production environments, the difference between single-site and multi-site systems can translate to significant capital cost savings by reducing the total number of programming stations required to meet production targets.

To accurately assess a programmer's production throughput, use this comprehensive formula: Effective UPH (Units Per Hour) = 3600 / (Handling Time + Programming Time + Verification Time + Data Transfer Time + Overhead). Request detailed timing breakdowns from vendors and validate claims with your own testing using representative devices, data file sizes, and production procedures. The system with the lowest advertised programming time may not deliver the best overall throughput if handling and overhead times are excessive. Pay particular attention to verification time, as comprehensive verification procedures are essential for quality assurance but can significantly impact overall cycle time.

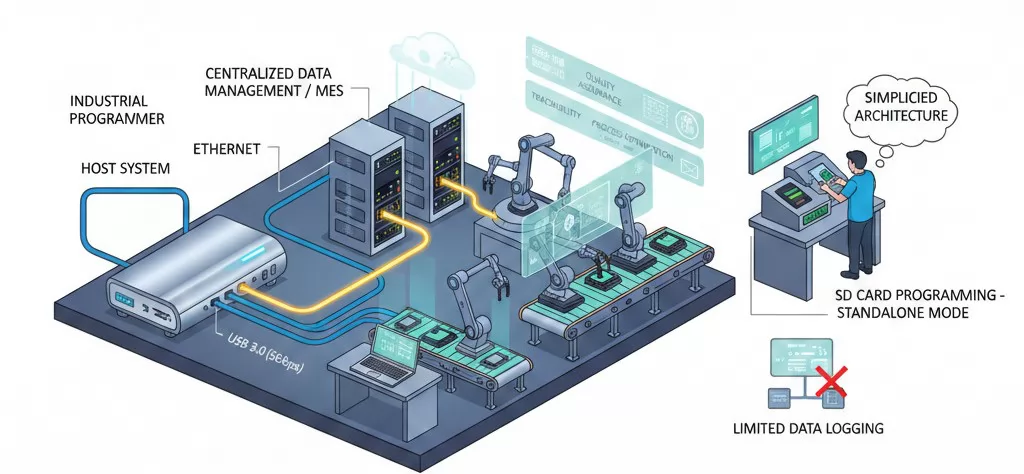

The data transfer interface between the programmer and host system significantly impacts overall production efficiency. USB 3.0 connections offer broad compatibility and sufficient bandwidth for most programming applications, with theoretical transfer rates of 5 Gbps providing headroom for large data files. However, for high-volume production environments programming large storage devices or requiring integration with centralized data management systems, Ethernet-based connections may offer advantages in terms of network integration, remote access capabilities, and centralized firmware distribution.

Consider how the programmer integrates with your existing production infrastructure. Modern industrial programmers should offer APIs and software development kits (SDKs) enabling integration with Manufacturing Execution Systems (MES), automated test equipment, and production management software. This integration capability becomes increasingly important as manufacturers pursue Industry 4.0 initiatives and seek to capture comprehensive production data for quality assurance, traceability, and process optimization. Look for programmers that support common industrial communication protocols and offer robust SDK documentation that facilitates integration development.

Some advanced programming systems offer SD card-based programming modes that enable standalone operation without host computer connectivity. This capability can simplify production line architecture by eliminating the need for dedicated programming workstations, though it may limit data logging and traceability capabilities compared to fully networked solutions.

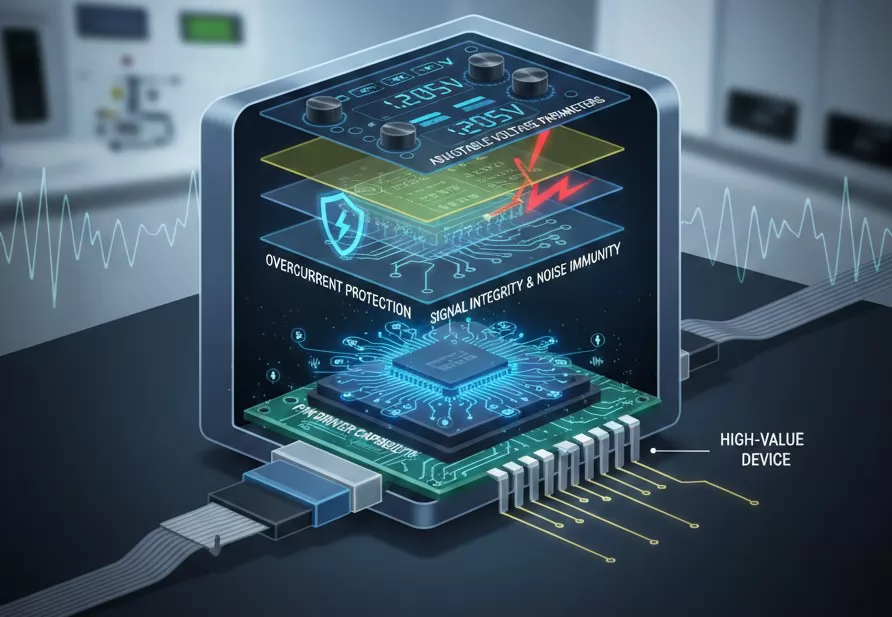

The electrical specifications of a programmer directly impact programming reliability and device safety. Programming voltage accuracy, drive strength, and signal integrity become critical when working with modern devices that operate at increasingly low voltage levels while requiring precise timing. Look for programmers that offer adjustable voltage parameters with fine granularity, allowing optimization for specific device requirements and accommodation of manufacturing variations across device lots.

Overcurrent protection represents an essential safety feature that prevents device damage during programming operations. Quality industrial programmers incorporate sophisticated protection circuits that detect abnormal current conditions and shut down programming operations before damage occurs. This protection is particularly important when programming high-value devices where a single failure can represent substantial financial loss. Additionally, examine the programmer's grounding scheme and noise immunity characteristics—production environments often contain significant electromagnetic interference from nearby equipment that can compromise programming reliability if the equipment is not properly designed.

The pin driver capability of a programmer determines its ability to reliably communicate with target devices, particularly those with challenging electrical characteristics or long connection paths. Industrial programmers should provide adequate drive strength to overcome connection resistance and capacitance while maintaining signal integrity across the programming interface.

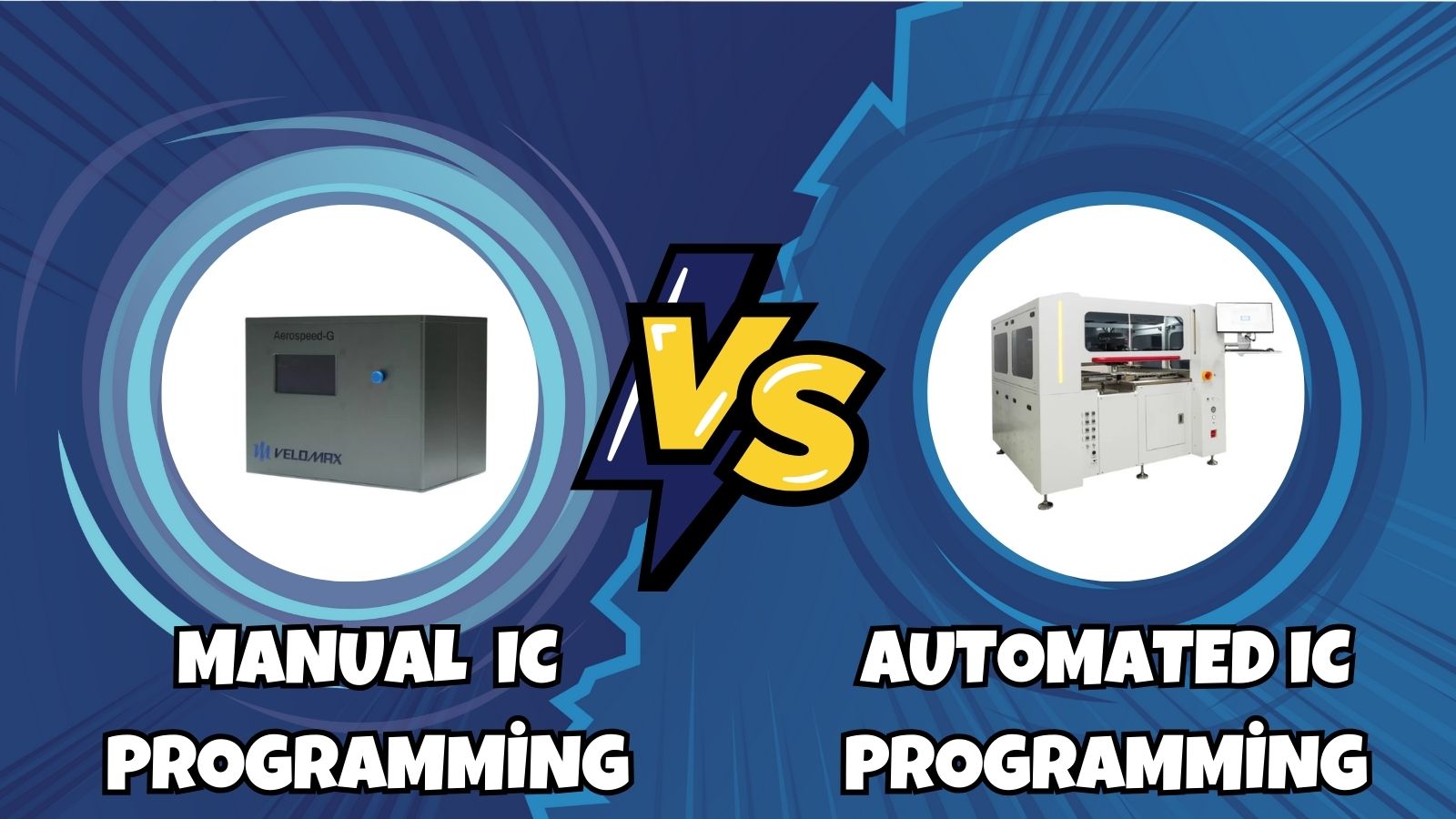

The fundamental architecture of your programming system shapes its capabilities, limitations, and suitability for specific production scenarios. Two primary approaches dominate industrial programming: off-line socket programming and in-system programming (ISP). Each offers distinct advantages and faces specific constraints that must be evaluated against your production requirements and operational context.

Off-line socket programming, also known as gang programming when multiple sites are involved, involves programming devices in dedicated sockets before they are assembled onto circuit boards. This approach offers maximum programming speed since the programmer has direct, optimized access to device pins without the constraints introduced by circuit board layout. Socket programming supports the widest range of device packages, including BGA devices that cannot be programmed through board-level connections due to their lack of accessible pins.

The primary consideration with socket programming is the socket adapter investment. Each device package type requires a specific socket adapter, and these adapters represent consumable items that wear over time and require periodic replacement. High-volume production programs should factor adapter lifecycle costs into total cost of ownership calculations. Quality socket adapters from reputable manufacturers can program hundreds of thousands of cycles before requiring replacement, while cheaper alternatives may need replacement after significantly fewer cycles, leading to higher long-term costs and production interruptions.

Socket programming systems range from manual single-site units to fully automated systems incorporating robotic handling. Manual systems suit lower-volume production or prototype programming, while automated handlers become essential for high-volume manufacturing. Automated systems can achieve throughput rates of 2000-3000 units per hour or more, depending on device characteristics and programming requirements. The investment in automated handling equipment typically pays for itself quickly in production environments where labor costs would otherwise limit throughput or where consistent handling quality is essential for yield optimization.

In-system programming (ISP) enables programming of devices after they have been assembled onto circuit boards, eliminating the need for socket adapters and separate handling. ISP connects to devices through standard interfaces like JTAG, SPI, UART, or custom protocols that are designed into the circuit board for testing and firmware update purposes. This approach offers significant advantages in terms of reduced handling costs, elimination of pre-programmed component inventory, and the ability to perform programming as part of the final test process.

The trade-offs with ISP include typically slower programming speeds compared to socket programming due to board-level signal integrity constraints, dependence on PCB layout quality, and the requirement for test points or connectors to be designed into the board. Careful attention to PCB layout, including appropriate buffering, signal termination, and power supply decoupling, can mitigate many of these concerns but requires coordination between electrical and mechanical engineering teams during the product design phase.

ISP programming often suits applications where field firmware updates are anticipated, as the same connectors and interfaces used for production programming can serve maintenance purposes throughout the product lifecycle. This dual-use capability can justify the ISP infrastructure investment by providing ongoing value beyond initial production programming, particularly for products with long expected service lives or those requiring frequent firmware revisions to address feature enhancements or security updates.

| Characteristic | Socket Programming | In-System Programming |

|---|---|---|

| Programming Speed | Highest (direct pin access) | Moderate (board-level constraints) |

| Device Package Support | Most comprehensive | Limited to ISP-capable devices |

| Initial Investment | Socket adapter costs | Test fixture integration |

| Operational Costs | Socket wear/replacement | Minimal consumables |

| Integration Complexity | Independent of board design | Requires board design coordination |

| Field Update Capability | Not applicable | Native support |

| Programming Reliability | Very High | High (with proper design) |

| Component Handling | Additional handling required | No additional handling |

The proliferation of high-density memory devices in modern electronics has introduced new programming challenges that traditional programmers may struggle to address. eMMC (embedded MultiMediaCard) and UFS (Universal Flash Storage) devices have become ubiquitous in smartphones, tablets, embedded systems, and IoT devices, offering high storage capacity in compact form factors. Programming these devices requires specialized knowledge and equipment optimized for their unique characteristics and high data transfer rates.

eMMC devices integrate flash memory with a sophisticated controller that handles wear leveling, error correction, and bad block management. The internal controller presents a standardized interface to the host system, abstracting the complexity of raw NAND flash management. However, this abstraction introduces programming considerations that differ from traditional flash devices and require specialized programmer capabilities.

eMMC programming typically operates through high-speed interfaces supporting data rates up to 400 MB/s or more in HS400 mode. The programmer must support these high-speed interfaces while maintaining signal integrity across the programming connection, which requires careful attention to PCB design and cable quality. Additionally, eMMC devices require proper initialization sequences, configuration of operating parameters, and management of internal partition structure including user data area, boot partitions, and RPMB (Replay Protected Memory Block) region.

Leading industrial programmers provide comprehensive eMMC support including partition management, boot region configuration, enhanced data reliability settings, and vendor-specific extensions. The programmer software should support common eMMC commands and provide flexibility to accommodate device-specific requirements from different manufacturers. As eMMC technology continues to evolve with larger capacities and faster interfaces, ensuring your programming equipment can support current and future device specifications is essential for protecting your investment.

NAND flash technology, the foundation of modern solid-state storage, presents unique programming challenges stemming from its inherent reliability characteristics. NAND flash cells degrade with each program/erase cycle, and manufacturing defects result in initial bad blocks that must be identified and managed during production programming. Without proper handling, these bad blocks can cause data corruption, system instability, and premature device failure, resulting in warranty returns and customer dissatisfaction.

Industrial programmers designed for NAND flash applications must implement sophisticated bad block management algorithms that map out defective blocks during initial formatting and ensure that subsequent programming operations avoid these areas while maintaining data integrity. The programmer should support standard NAND management protocols while providing flexibility to accommodate device-specific requirements from different flash manufacturers including Samsung, SK Hynix, Micron, Kioxia, and Western Digital.

As NAND flash geometries continue to shrink and multi-level cell (MLC), triple-level cell (TLC), and quad-level cell (QLC) technologies become common, these management requirements become increasingly complex. The increased bit density comes with reduced endurance and greater sensitivity to programming parameters, requiring more sophisticated algorithms to maintain reliability while achieving acceptable programming throughput.

Velomax Systems has developed specialized expertise in high-density memory programming, including advanced eMMC and NAND flash programming capabilities. Our programmers support the latest device specifications while maintaining backward compatibility with legacy devices. We offer comprehensive support for security features including OTP (One-Time Programming) regions, cryptographic acceleration, and secure boot configuration. Contact our technical team to discuss your specific memory programming requirements and discover how our solutions can optimize your production programming operations.

Selecting the appropriate industrial IC programmer requires systematic evaluation of your production requirements and operational constraints. The following framework poses essential questions that should guide your evaluation process and ensure that your investment delivers maximum value throughout its operational lifecycle.

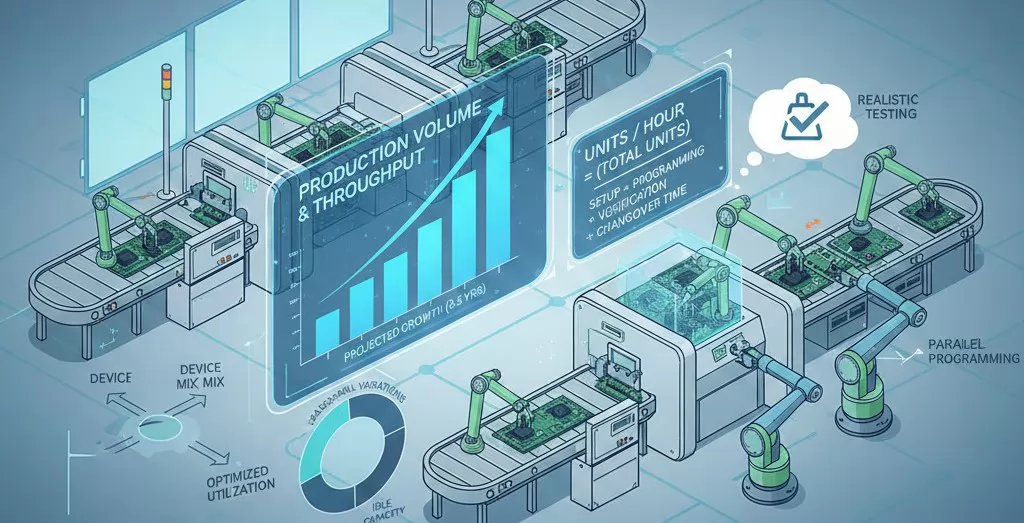

Understanding your production volume and throughput requirements establishes the foundation for all subsequent selection decisions. Consider both current production volumes and projected growth over a three to five year horizon—selecting a system that barely meets today's requirements may necessitate premature replacement as production scales. Examine peak demand periods and seasonal variations to ensure the selected system provides adequate capacity for high-demand periods without excessive idle capacity during slower periods that represents underutilized capital investment.

Calculate required throughput in terms of units per hour, considering the full production cycle including setup, programming, verification, and changeover times. The programmer's specification sheets may present optimistic throughput figures based on ideal conditions, so validate these claims with realistic testing using representative devices and data files. Consider whether parallel programming capabilities could multiply effective throughput and whether your device mix and production scheduling would allow utilization of these capabilities without excessive changeover downtime.

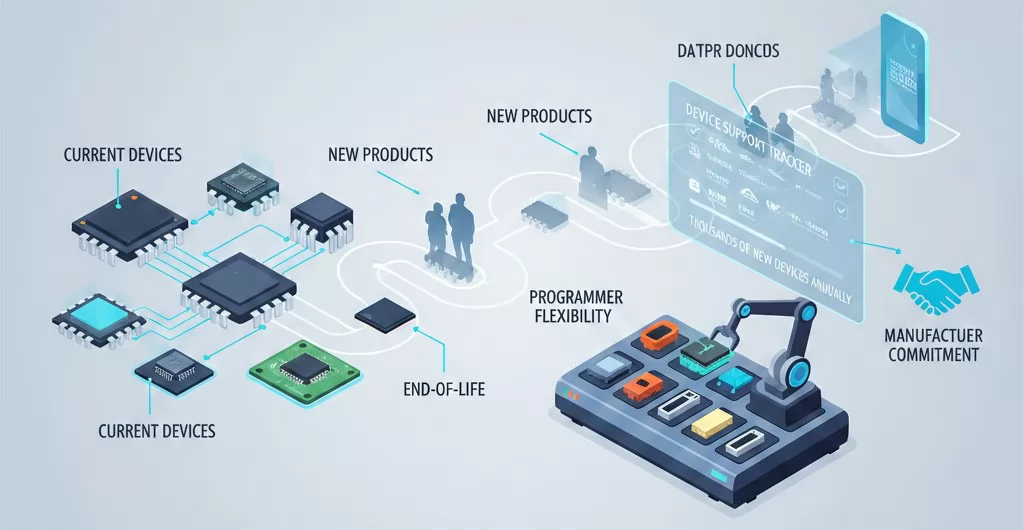

The diversity of devices in your production portfolio directly impacts the required programmer capabilities and adapter investments. A production environment focused on a single device type may achieve optimal economics with a dedicated programming system, while facilities programming dozens of different devices require broader flexibility to avoid excessive adapter inventory. Document your current device portfolio and anticipated changes over the planning horizon, including new product introductions and end-of-life transitions.

Examine the manufacturer's commitment to ongoing device support and their process for adding new devices to their supported list. Semiconductor manufacturers introduce thousands of new devices annually, and your programming equipment must keep pace with these developments to avoid becoming a constraint on product development and production flexibility. Evaluate the manufacturer's track record for timely support of newly released devices and their responsiveness to customer requests for device support additions.

Industries subject to quality management standards like ISO 9001, IATF 16949 for automotive, or AS9100 for aerospace mandate comprehensive traceability of production processes, including programming operations. Evaluate whether the programmer provides adequate logging and documentation capabilities to satisfy your quality system requirements and customer audit expectations. Consider what data must be captured for each programming operation, how this data is stored and protected, and how it integrates with your quality management systems and enterprise resource planning platforms.

Advanced industrial programmers offer comprehensive data logging that records programming parameters, device identifiers, timestamp information, serial numbers, and programming results for every operation. This data enables root cause analysis of any programming failures and provides the documentation necessary for customer audits and regulatory compliance. Some systems offer secure data logging with cryptographic protection to ensure the integrity of quality records throughout the retention period, preventing unauthorized modification that could compromise product traceability.

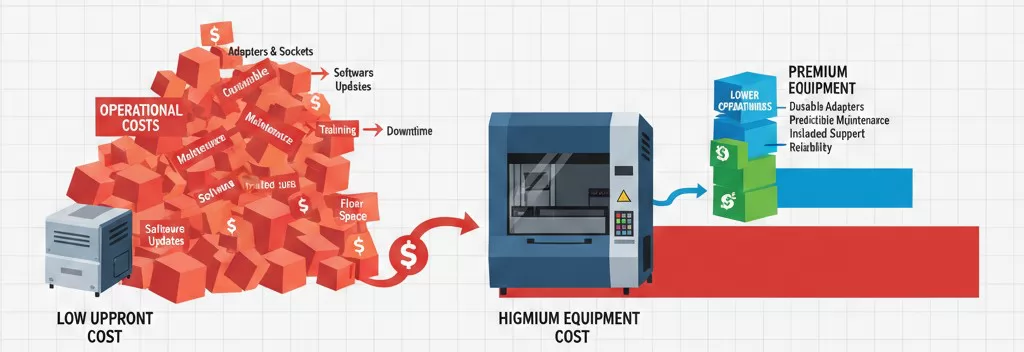

Initial purchase price represents only a fraction of the total cost of ownership for industrial programming equipment. A comprehensive TCO (Total Cost of Ownership) analysis must account for adapter and socket costs (including replacement cycles), consumables, maintenance and repair expenses, software support and update costs, operator training requirements, floor space costs, and the cost of production interruptions due to equipment issues. This analysis often reveals that lower-priced equipment with higher operational costs exceeds the lifecycle cost of premium equipment designed for industrial use.

Calculate the cost per programmed unit by dividing total lifecycle costs by expected production volume over the equipment's useful life. This metric enables meaningful comparison between alternatives that may have different upfront costs and operational characteristics. Consider the value of reliability—a programmer that experiences less unplanned downtime delivers more production time, reducing effective cost per unit even if its base specification is comparable. Factor in the cost of engineering time required to support and troubleshoot equipment issues, which can be substantial for less mature or poorly supported platforms.

| Cost Category | Socket Programming | In-System Programming |

|---|---|---|

| Equipment Cost | Moderate to High | Moderate |

| Adapter/Socket Costs | High (per device type) | Low (fixture integration) |

| Consumables | Moderate to High | Low |

| Maintenance | Moderate | Low |

| Training | Standard | Enhanced (PCB coordination) |

| Typical TCO Range | Higher initial, predictable ongoing | Lower initial, variable ongoing |

| Break-Even Volume | High volume recommended | Flexible across volumes |

The substantial investment in industrial programming equipment makes it essential to avoid common selection and implementation mistakes that can compromise returns and create operational problems. Understanding these pitfalls enables more informed decision-making and positions your organization for programming operation success.

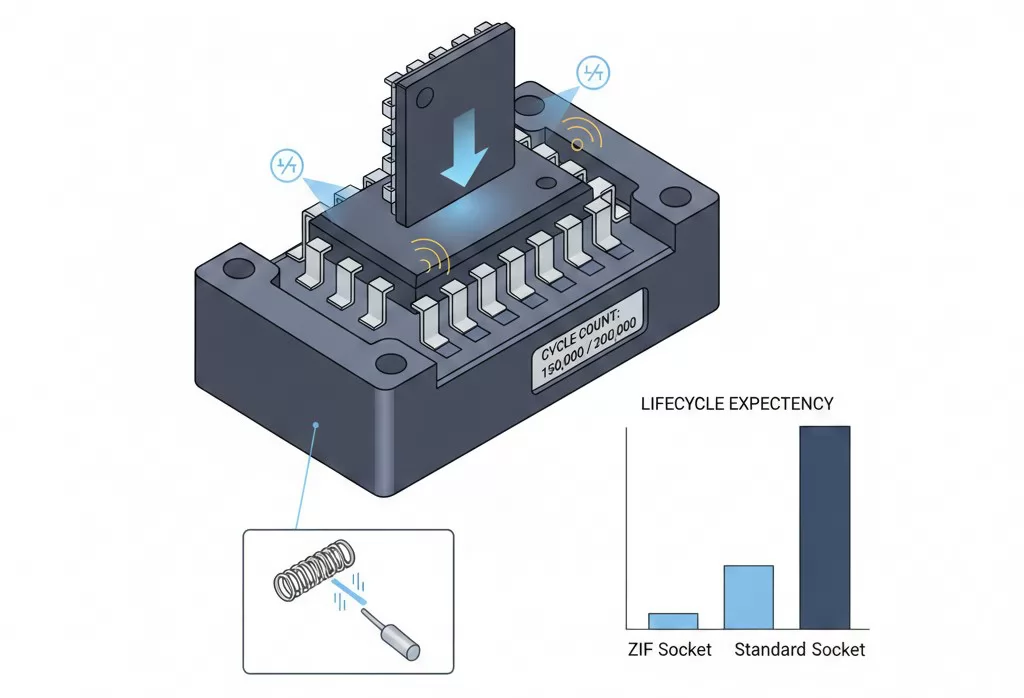

Socket adapters represent a significant ongoing expense that is frequently underestimated during initial procurement. The contact springs that establish electrical connections with device pins wear with each insertion cycle, eventually degrading to the point where reliable programming can no longer be assured. Different socket types have different lifecycles—high-quality ZIF (Zero Insertion Force) sockets may achieve hundreds of thousands of cycles, while standard sockets for certain package types may require replacement after tens of thousands of cycles. This wear pattern creates not only direct replacement costs but also the risk of programming failures that may not be immediately detected.

When evaluating socket programming systems, request detailed information about adapter lifecycle expectations from manufacturers and factor anticipated replacement costs into your total cost of ownership analysis. Consider whether the socket design allows for contact replacement or requires complete adapter replacement. Evaluate the manufacturer's reputation for socket quality, their socket manufacturing capabilities, and support policies for discontinued adapter types as product families evolve. Establishing a preventive replacement schedule based on actual usage rather than calendar time can help maintain programming quality while optimizing replacement costs.

Industrial programming equipment operates in demanding environments that differ significantly from clean laboratory settings. Consider ambient temperature and humidity conditions, the presence of electromagnetic interference from nearby production equipment like motors, welders, and high-frequency devices, power quality and grounding infrastructure, and space constraints in your production layout. Equipment selected without adequate attention to these factors may experience reliability issues or require expensive infrastructure modifications that delay production ramp-up.

Evaluate power quality requirements and ensure that your facility can provide stable, clean power to the programming equipment. Industrial environments often contain significant electrical noise from various sources that can interfere with precision programming operations. Quality programming equipment incorporates appropriate filtering and shielding, but extreme environments may require additional measures such as dedicated power circuits, power conditioning equipment, or electromagnetic shielding enclosures. Consider whether your facility can provide adequate environmental controls including temperature, humidity, and dust filtration to maintain optimal equipment performance.

Marketing materials frequently emphasize peak programming speed, which represents optimal conditions that may differ substantially from real-world performance. A programmer capable of 5-second programming for small data files may require 15 seconds or more for production data files, and the difference between advertised and actual throughput multiplies significantly over millions of programming cycles. This discrepancy between specification and reality can lead to capacity shortfalls that disrupt production planning and customer commitments.

Request detailed timing breakdowns from vendors including separate figures for device handling, data transfer, programming, verification, and any idle or setup time. Validate claims with your own testing using representative devices, data files reflecting actual production file sizes, and production procedures including any quality checkpoints or re-work handling. Consider the impact of device handling, changeover procedures, and quality control checks on effective throughput. The programmer with the best headline specification may not deliver the best overall production throughput when all factors are considered, particularly for mixed-product environments where changeover frequency impacts effective utilization.

Successful deployment of industrial programming equipment extends beyond the selection process to encompass installation, configuration, training, and ongoing operation. Following established best practices throughout implementation maximizes your return on investment and establishes a foundation for long-term operational excellence.

Installation should be performed by qualified personnel following manufacturer guidelines, with particular attention to proper grounding, environmental conditions, and connectivity to host systems and network infrastructure. Comprehensive documentation of the installation process and configuration settings facilitates maintenance and troubleshooting throughout the equipment lifecycle. Validate equipment performance against specifications immediately following installation to identify any issues while warranty coverage remains in effect.

Operator training should encompass not only basic equipment operation but also troubleshooting procedures, maintenance requirements, and escalation protocols for equipment issues. Well-trained operators can identify and resolve minor issues before they escalate, maintain equipment in optimal condition through proper care and preventive maintenance, and recognize when professional service is required. Ongoing refresher training ensures that skills remain current as equipment evolves and procedures are updated. Consider implementing competency assessments to verify operator proficiency and identify areas where additional training would be beneficial.

The rapid pace of semiconductor technology evolution demands that industrial programming equipment remain capable of supporting new devices throughout its useful life. Future-proofing strategies ensure that your investment continues to deliver value as technology advances and production requirements evolve, protecting your capital investment and maintaining production flexibility.

Select equipment from manufacturers with demonstrated commitment to ongoing development and support. Evaluate their track record for software updates, device support additions, and hardware improvements over time. Consider whether the equipment architecture allows for upgrades or expansions that extend capabilities without complete replacement. Modular designs that accommodate additional programming sites, enhanced interfaces, expanded device support, or upgraded processing capabilities provide flexibility to adapt to changing requirements without full system replacement.

The emergence of new memory technologies, secure boot architectures, and specialized programming requirements will continue to reshape programming demands. Stay informed about industry trends through technical publications, conferences, and manufacturer communications. Maintain an ongoing relationship with equipment suppliers to understand upcoming capabilities and plan for technology transitions. Organizations that anticipate technology evolution and select flexible, upgradeable solutions position themselves to adapt more quickly and maintain competitive manufacturing operations.

Velomax Systems offers comprehensive industrial programming solutions backed by expert technical support and industry-leading reliability. Our team can evaluate your specific requirements and recommend the optimal programming configuration for your production environment.

Request a ConsultationSelecting industrial-grade IC programming equipment requires careful evaluation of technical specifications, production requirements, and total cost of ownership across the equipment lifecycle. The stakes are substantial—programming equipment that fails to meet production requirements can create bottlenecks, compromise quality, and undermine manufacturing efficiency. Conversely, well-selected programming equipment becomes a strategic asset that enables competitive manufacturing operations and supports business growth.

The considerations outlined in this guide—device support breadth, programming speed accuracy, architectural options between socket and in-system programming, memory device capabilities including eMMC and NAND requirements, and comprehensive total cost of ownership analysis—provide a framework for systematic evaluation of industrial programmer alternatives. By approaching the selection process with thorough analysis and clear requirements, manufacturing organizations can make informed investments that deliver lasting value and support long-term operational excellence.

Velomax Systems stands ready to support your industrial programming requirements with comprehensive solutions backed by deep technical expertise across memory programming, microcontroller programming, and automated handling systems. Our commitment to customer success extends beyond equipment sales to encompass ongoing support, training, and consultation that helps optimize your programming operations and adapt to evolving requirements. Contact our team to discuss how our solutions can address your specific manufacturing challenges and contribute to your production success.

Our technical team is available to help you evaluate your requirements and recommend the optimal programming solution for your production environment. Contact Velomax Systems today to start the conversation.

Contact Us

Discover this amazing content and share it with your network!

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.