As Electric Vehicles (EVs) transition into "computers on wheels," the demand for high-performance storage has skyrocketed. Historically, eMMC (embedded MultiMediaCard) was the standard for automotive infotainment and navigation systems. However, the rise of Advanced Driver Assistance Systems (ADAS), digital cockpits, and autonomous driving functions has pushed eMMC to its physical limits.

UFS (Universal Flash Storage) has emerged as the successor, offering a significant leap in data throughput. Unlike eMMC’s half-duplex interface—which can only read or write at one time—UFS utilizes a full-duplex serial interface. This allows for simultaneous read and write operations, drastically reducing latency and enhancing the responsiveness of critical EV software systems.

In the context of EV manufacturing, the shift to UFS represents more than just a speed upgrade; it is a fundamental change in how data is handled during the production cycle. With UFS 3.1 and 4.0 standards becoming the norm, the complexity of UFS programming has increased, requiring specialized hardware that can handle higher densities without compromising the integrity of the automotive firmware.

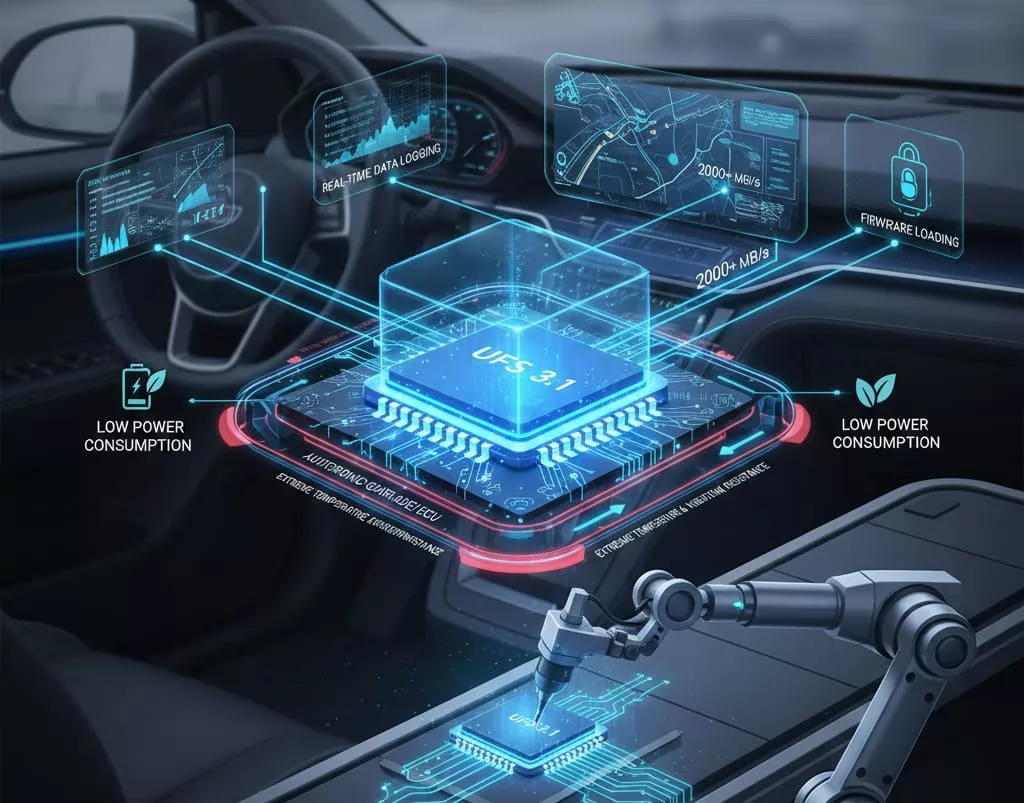

The transition to UFS in electric vehicle architecture is driven by specific technical requirements that traditional storage solutions cannot meet. In a modern EV, the storage medium must support high-speed booting, real-time data logging, and the massive throughput required for high-resolution 3D maps and sensor fusion.

Key technical advantages include:

For manufacturers, these advantages translate into a more fluid user experience for the end-consumer. However, from a production standpoint, the increased complexity of UFS requires sophisticated IC programming solutions that can interface with these high-speed serial protocols without creating bottlenecks on the assembly line.

Transitioning from eMMC to UFS is not a simple "plug-and-play" upgrade for production lines. The technical architecture of UFS introduces several hurdles that manufacturers must overcome to maintain high throughput and yield rates.

The primary challenge lies in the High-Speed Differential Signaling used by UFS. Unlike the simpler parallel interface of eMMC, UFS utilizes M-PHY and UniPro protocols. This requires programming equipment with high signal integrity to prevent data corruption during the flashing process. Furthermore, the massive increase in storage capacity—often reaching 256GB or 512GB in modern EVs—means that traditional programmers may take several minutes to flash a single chip, creating a massive bottleneck in the manufacturing flow.

Additional challenges include:

To address these issues, Tier-1 automotive suppliers are increasingly moving away from general-purpose tools in favor of automated programming systems specifically engineered for high-density automotive devices.

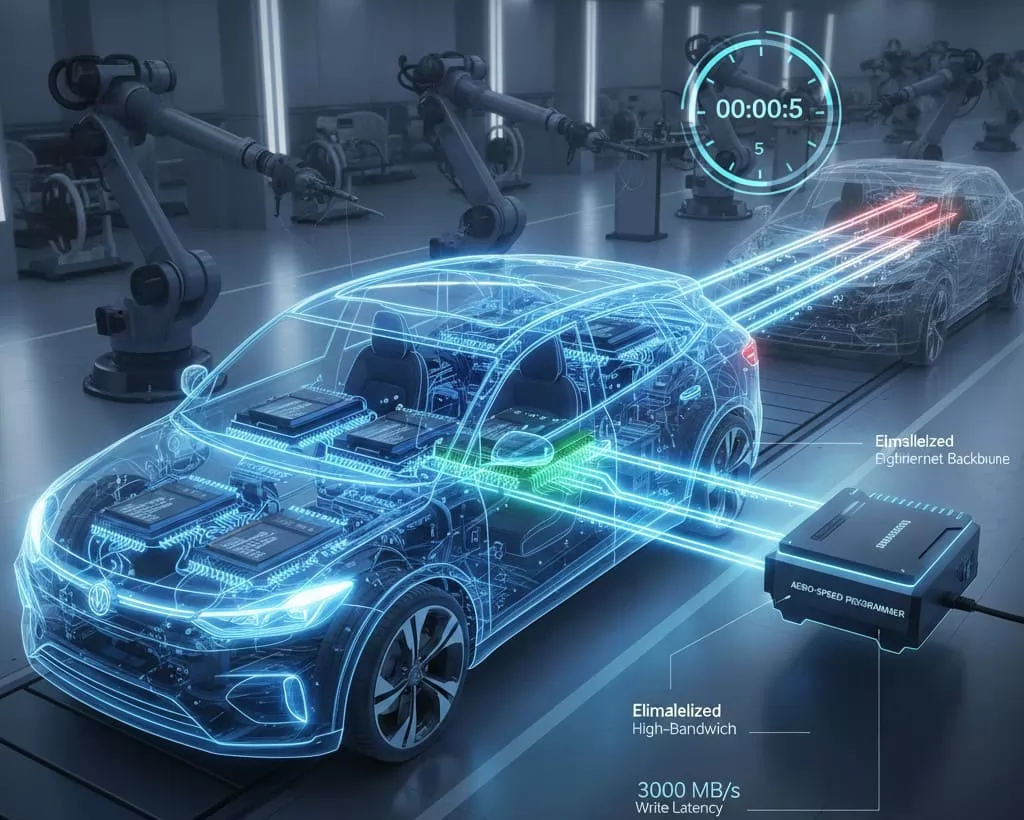

Modern Electric Vehicles are data-intensive environments. With UFS 3.1 and 4.0 storage capacities frequently reaching 256GB to 1TB to support high-definition mapping and ADAS logs, the volume of data that must be flashed during production has increased exponentially. Traditional programming methods often fail to keep pace, leading to costly idle time on the manufacturing floor.

To combat this, the industry is moving toward Aero-Speed programming—a next-generation approach designed specifically for ultra-high-density devices. Unlike standard programmers that may bottleneck at the data transfer stage, Aero-Speed systems utilize optimized communication paths to maximize the theoretical bandwidth of the UFS interface.

Key features of this high-speed approach include:

For EV manufacturers, adopting Aero-Speed programming is not just about speed; it is about scalability. As software-defined vehicles continue to grow in complexity, the ability to flash massive firmware images flawlessly in seconds rather than minutes is the difference between an efficient production line and a bottlenecked one.

At the heart of high-performance UFS programming lies the FPGA (Field-Programmable Gate Array). Unlike general-purpose processors that rely on software-driven execution, FPGA-based architectures allow for hardware-level control over signal timing and data flow. This is critical when dealing with the strict timing requirements of the UFS M-PHY physical layer and UniPro link layer.

The use of advanced FPGA architecture provides several technical advantages for EV electronic manufacturing:

For engineering teams, an FPGA-centric design means the programming system is future-proof. As new UFS standards emerge or EV firmware security protocols evolve, the system can be updated at the logic level to accommodate these changes without requiring a complete hardware overhaul.

In the automotive industry, the cost of failure is exceptionally high. A single corrupted bit in an EV’s storage can lead to system-wide failures, necessitating expensive recalls and compromising passenger safety. Therefore, UFS programming must adhere to "zero-defect" manufacturing principles, ensuring that every chip is flashed with 100% accuracy.

To achieve automotive-grade reliability, programming systems must implement rigorous validation protocols:

By integrating these reliability checks directly into the programming workflow, manufacturers can ensure that the UFS devices powering digital cockpits and ADAS modules are robust enough for a decade of service on the road.

At the heart of high-performance UFS programming lies the FPGA (Field-Programmable Gate Array). Unlike general-purpose processors that rely on software-driven execution, FPGA-based architectures allow for hardware-level control over signal timing and data flow. This is critical when dealing with the strict timing requirements of the UFS M-PHY physical layer and UniPro link layer.

The use of advanced FPGA architecture provides several technical advantages for EV electronic manufacturing:

For engineering teams, an FPGA-centric design means the programming system is future-proof. As new UFS standards emerge or EV firmware security protocols evolve, the system can be updated at the logic level to accommodate these changes without requiring a complete hardware overhaul.

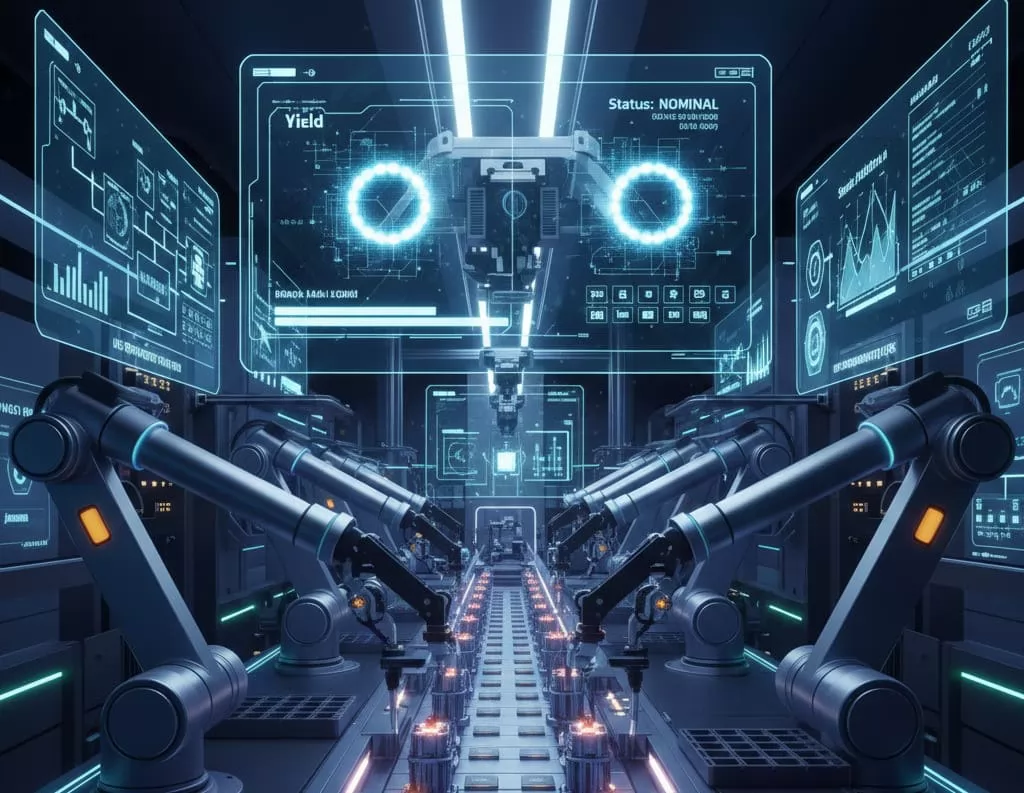

To meet the massive production volumes required by the global EV market, manual programming is no longer a viable option. Modern smart factories require the seamless integration of UFS programming into fully automated production lines. This is achieved through high-speed robotic systems capable of handling thousands of chips per hour with minimal human intervention.

The core of an automated UFS programming solution involves several critical components:

By automating the UFS programming process, EV manufacturers can achieve 24/7 operation, eliminate human error, and significantly reduce the total cost of ownership (TCO) for their electronic production infrastructure.

The automotive industry is currently witnessing a rapid migration from UFS 3.1 to the UFS 4.0 standard. As of 2025, UFS 4.0 has become the benchmark for next-generation Electric Vehicles, particularly those integrating Level 3 autonomous driving and AI-driven digital cockpits. This evolution is not merely about incremental speed; it represents a fundamental shift in data architecture.

UFS 4.0, powered by the MIPI M-PHY v5.0 physical layer and UniPro v2.0 transport layer, delivers double the bandwidth of its predecessor. While UFS 3.1 offers a maximum interface speed of 23.2 Gbps, UFS 4.0 reaches up to 46.4 Gbps per device, enabling sequential read speeds of approximately 4,200 MB/s.

Critical advantages of UFS 4.0 for the EV sector include:

For manufacturers, this means that programming infrastructure must be future-proof. As data densities move toward 1TB and beyond, the programming systems of today must be capable of supporting the Gear 5 (HS-G5) speeds of UFS 4.0 to ensure that the production lines of tomorrow remain efficient and competitive.

Velomax is a leading innovator in the field of high-speed programming, bridging the gap between hardware mastery and software excellence. With 10 years of hardware design expertise and 20 years of software development experience, Velomax is dedicated to elevating industrial production through user-driven innovation.

In an era defined by AI advancement and global digital transformation, Velomax specializes in high-speed programmers for high-density devices. Our core focus includes UFS for electric vehicles, eMMC for smart home appliances, and SPI Flash for complex electronic equipment.

Ready to optimize your EV production line with the latest in UFS programming technology? Connect with our experts at Velomax to discuss your high-speed programming requirements.

Discover this amazing content and share it with your network!

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.