In the landscape of modern semiconductor manufacturing, the Field Programmable Gate Array (FPGA) has transitioned from a niche component to the core engine of high-performance IC programming systems. Unlike traditional general-purpose microcontrollers (MCUs) that rely on a fixed instruction set and sequential execution, an FPGA-based architecture allows for the implementation of custom logic circuits directly at the hardware level. This capability is essential for managing the high-speed data rates required by contemporary storage technologies.

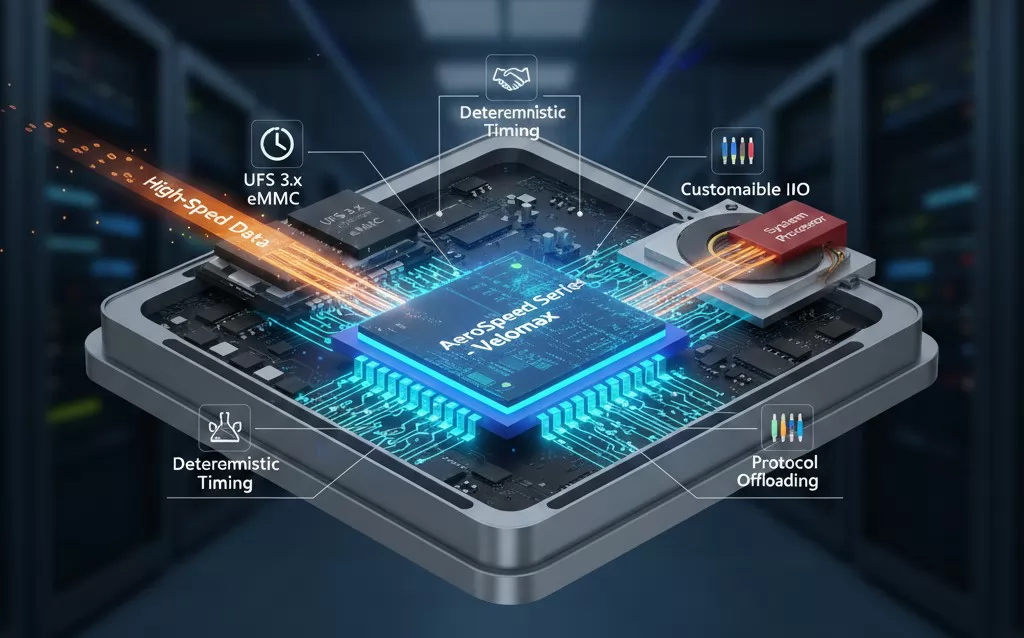

For high-density devices such as UFS (Universal Flash Storage) and eMMC (embedded MultiMediaCard), the programming process is no longer just about moving data; it is about managing complex, high-frequency signal protocols with nanosecond precision. The FPGA serves as a programmable bridge that can be tailored to match the specific timing diagrams and electrical characteristics of various IC families. By hardware-coding the communication protocols, programming systems can achieve a level of throughput and reliability that software-driven alternatives cannot sustain.

At Velomax, the integration of AeroSpeed Series technology utilizes this FPGA advantage to ensure that the programming cycle is optimized for the physical limits of the silicon, rather than being bottlenecked by the programmer's internal architecture.

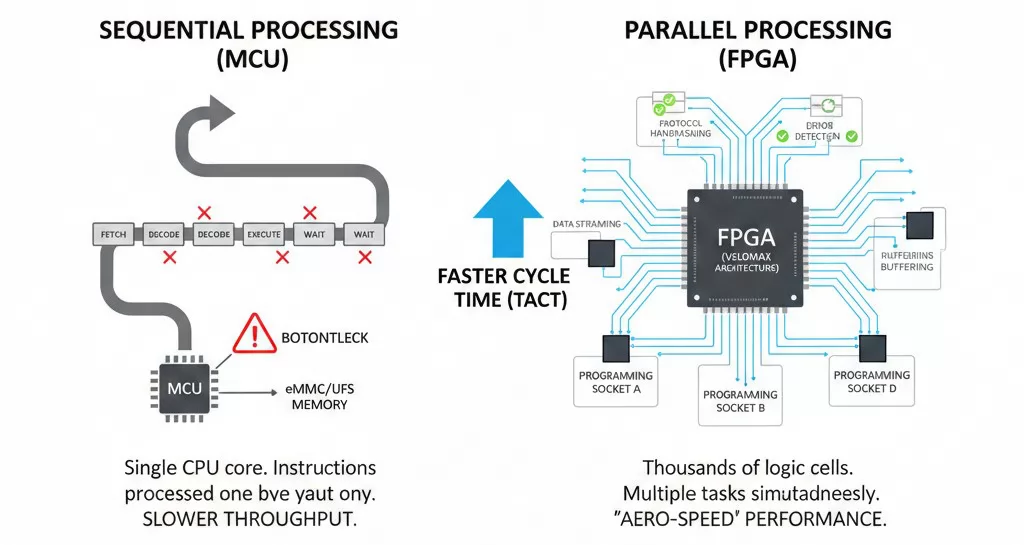

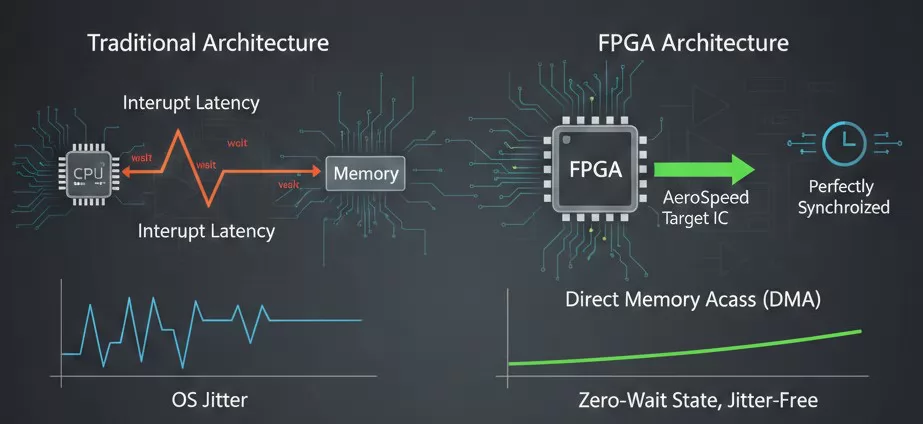

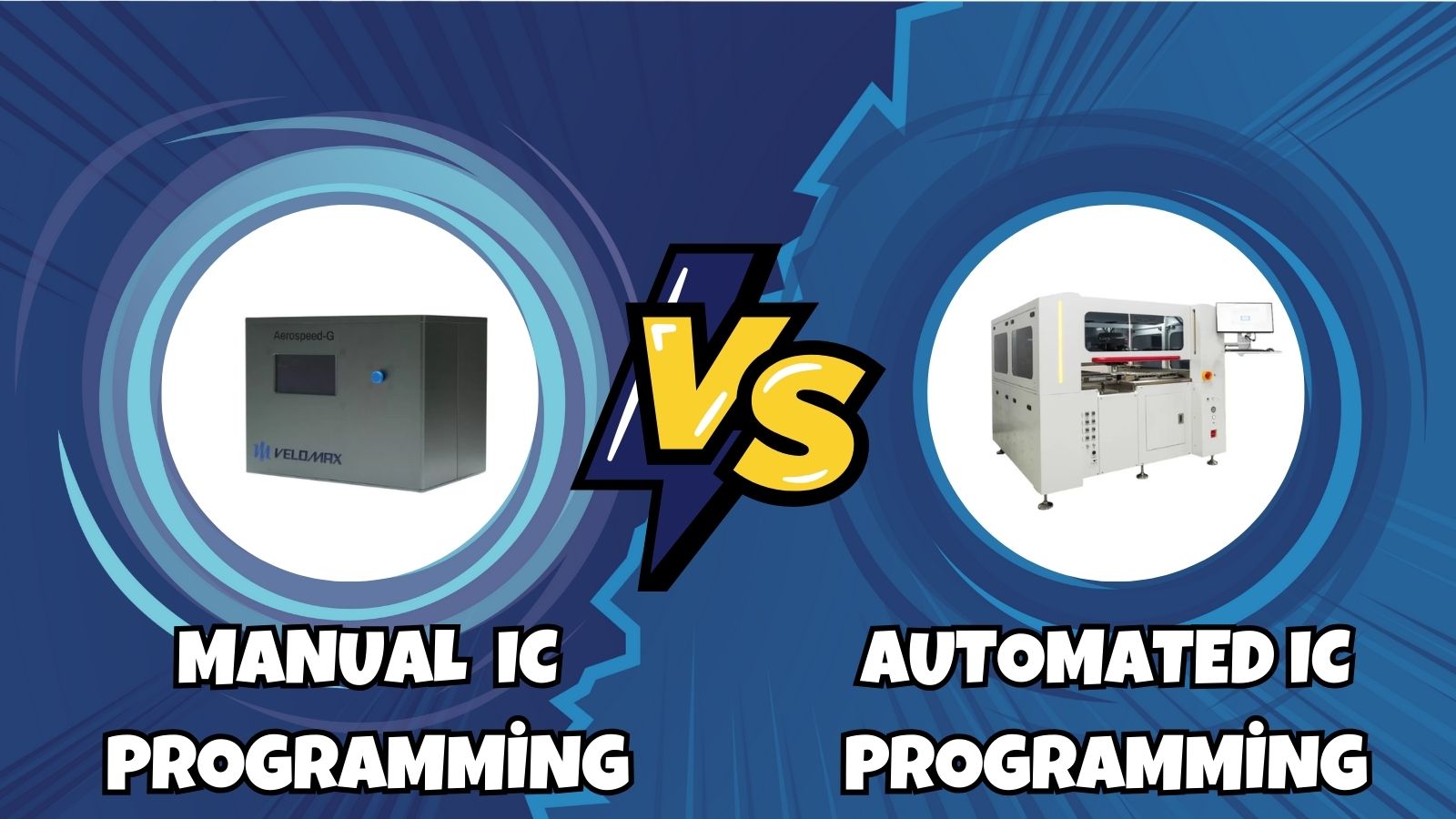

The fundamental limitation of traditional Microcontroller Units (MCUs) in high-speed programming lies in their sequential execution model. An MCU processes instructions one by one through its CPU core. When dealing with high-density memory devices like eMMC or UFS, the overhead of fetching, decoding, and executing instructions creates a "bottleneck" that limits the maximum data transfer rate. As the clock speed of the target IC increases, the MCU-based programmer often struggles to keep up, leading to idle cycles and slower production throughput.

In contrast, the FPGA architecture utilized in Velomax systems operates on a principle of massive parallelism. Instead of a single CPU executing instructions, an FPGA consists of thousands of logic cells that can be configured to perform multiple tasks simultaneously. This allows the programmer to handle data streaming, protocol handshaking, and error detection in parallel, without one process delaying the other. This architectural advantage is what enables the "aero-speed" performance required for modern automated production lines.

For high-volume manufacturing, the difference between sequential and parallel processing translates directly into Cycle Time (TACT). By leveraging our 20 years of software innovation and 10 years of hardware mastery, Velomax ensures that the FPGA logic is optimized to shave seconds off every programming cycle, a critical factor for the smart home and electric vehicle industries.

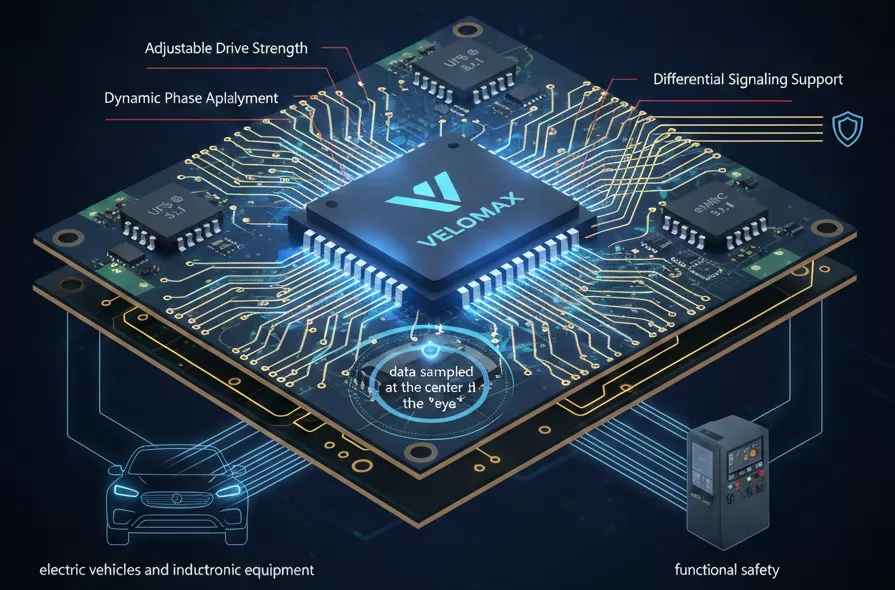

As IC technologies evolve, the transition to high-speed interfaces like UFS 3.1 (M-PHY) and eMMC 5.1 (HS400) has introduced significant challenges for signal integrity. Operating at frequencies in the gigahertz range, these protocols are highly sensitive to electromagnetic interference (EMI), signal reflection, and crosstalk. In a high-volume production environment, even a minor signal degradation can lead to high failure rates or "soft" errors that compromise the long-term reliability of the end product.

The FPGA-based architecture of Velomax programmers is uniquely equipped to handle these high-frequency demands. Unlike fixed-function hardware, the programmable I/O buffers within an FPGA allow for precise control over electrical parameters. This ensures that the communication between the programmer and the high-density memory device remains stable, even at peak transfer speeds.

By maintaining superior signal integrity, the AeroSpeed Series minimizes the risk of data corruption during the flashing process. This technical rigor is particularly critical for electric vehicles and industrial electronic equipment, where data accuracy is a matter of functional safety. Velomax leverages its decade of hardware mastery to design signal paths that meet these exacting industrial standards.

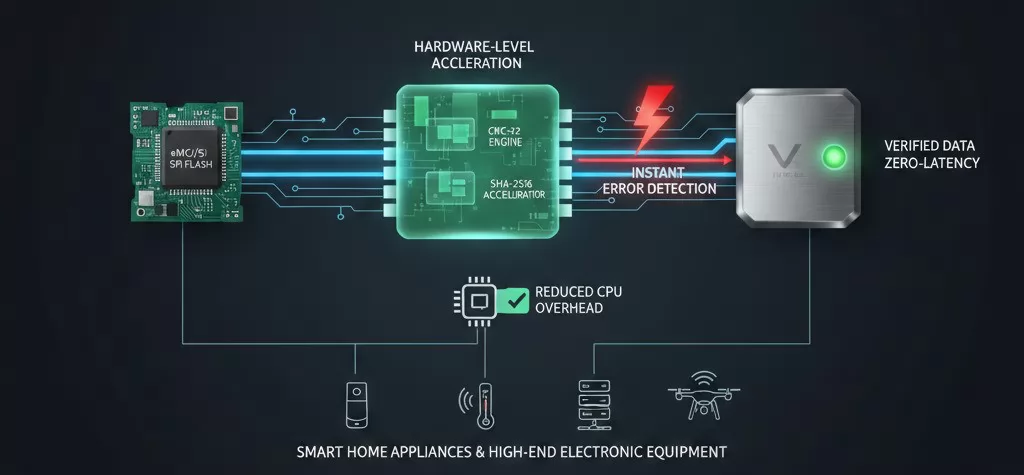

In IC programming, writing the data is only half the task; ensuring the integrity of that data through rigorous verification is equally critical. For high-density devices like eMMC and SPI Flash, verification often involves reading back gigabytes of data and performing complex Cyclic Redundancy Checks (CRC) or checksum calculations. In software-based systems, these calculations are performed by the CPU, which adds significant latency and increases the overall TACT (Total Actual Cycle Time).

The FPGA architecture enables hardware-level acceleration of these verification tasks. Instead of passing data back to a central processor, the FPGA implements dedicated logic blocks designed specifically for CRC-32, SHA-256, or other verification algorithms. This allows the checksum to be calculated in real-time as the data streams through the hardware, effectively making the verification process "zero-latency."

This hardware mastery is a hallmark of the AST Series. By offloading these intensive tasks to optimized FPGA gates, Velomax ensures that even the largest memory chips are programmed and verified with a level of precision and speed that meets the demanding requirements of smart home appliances and high-end electronic equipment.

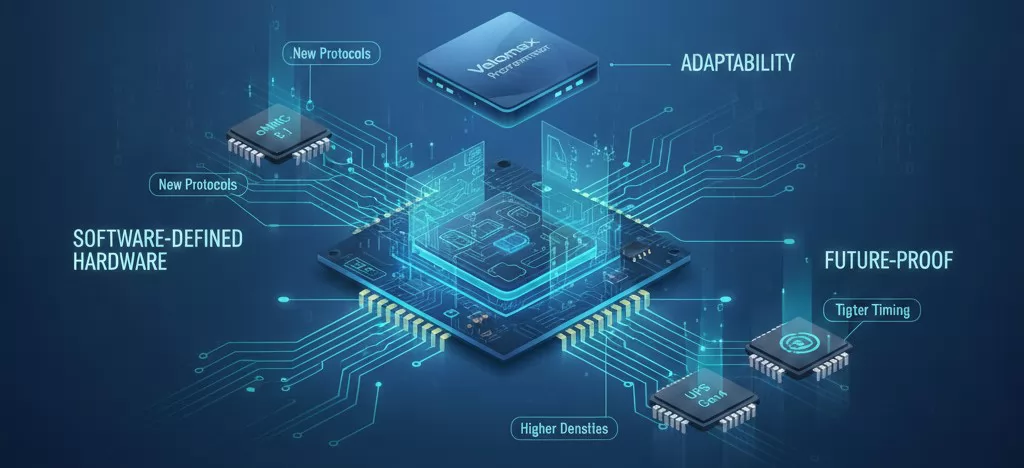

The semiconductor industry is characterized by rapid evolution, with new protocols, higher densities, and tighter timing requirements emerging every few years. For manufacturing facilities, investing in programming hardware that becomes obsolete with the next generation of ICs is a significant financial risk. An FPGA-based architecture mitigates this risk through its inherent reconfigurability—essentially providing "software-defined hardware."

Unlike Application-Specific Integrated Circuits (ASICs) which have fixed logic, the internal gates of an FPGA can be reprogrammed via firmware updates. This means that a Velomax programmer purchased today for eMMC 5.1 can be updated to support future high-speed standards or specialized proprietary protocols without requiring a complete hardware overhaul. This flexibility ensures that the equipment evolves alongside the technology it serves.

With 20 years of software development experience, Velomax specializes in optimizing these logic updates to ensure they are as seamless as a standard software patch. This technological leadership allows our customers to adapt to market shifts in AI and digital transformation without the downtime associated with procuring new hardware.

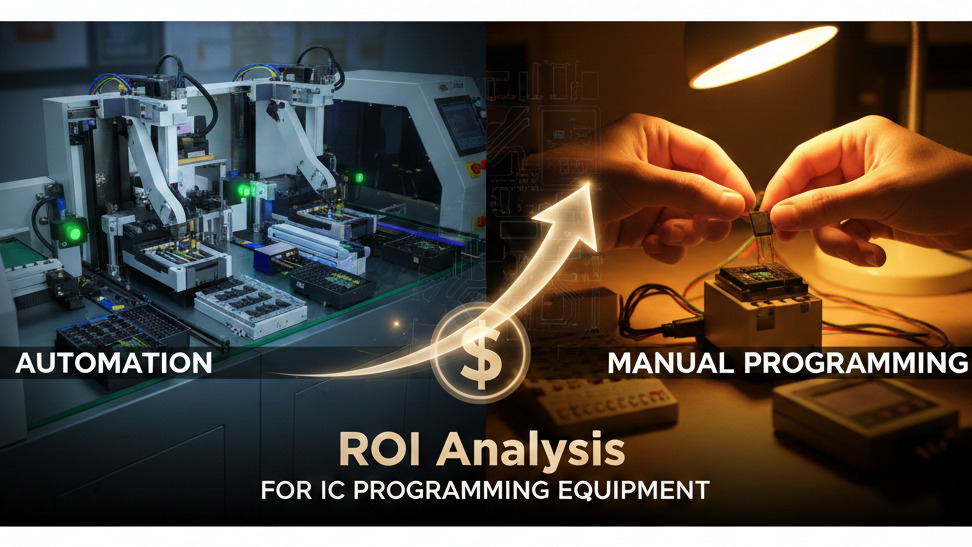

In the world of B2B manufacturing, time is the ultimate currency. When programming high-density devices like 128GB UFS or 64GB eMMC chips, even a delay of a few milliseconds per block can accumulate into minutes of lost productivity per shift. Traditional programming architectures often suffer from interrupt latency—the time the processor spends switching between tasks. In a high-speed data transfer environment, these micro-delays break the "flow" of data, forcing the target IC to wait for the next command packet.

FPGA architecture solves this by implementing Direct Memory Access (DMA) and hardware-level state machines. Because the logic is hard-wired into the FPGA gates, there is no operating system jitter or CPU context switching. Data moves from the system buffer to the target IC at a deterministic, constant rate. This architectural efficiency is what allows the AeroSpeed Series to achieve near-theoretical maximum speeds for every supported protocol.

For engineers managing high-volume production for smart home appliances or Aero-speed performance applications, minimizing latency isn't just about speed—it's about maximizing the ROI of the entire automation line. Velomax’s 10 years of hardware mastery ensures that every nanosecond is engineered for maximum throughput.

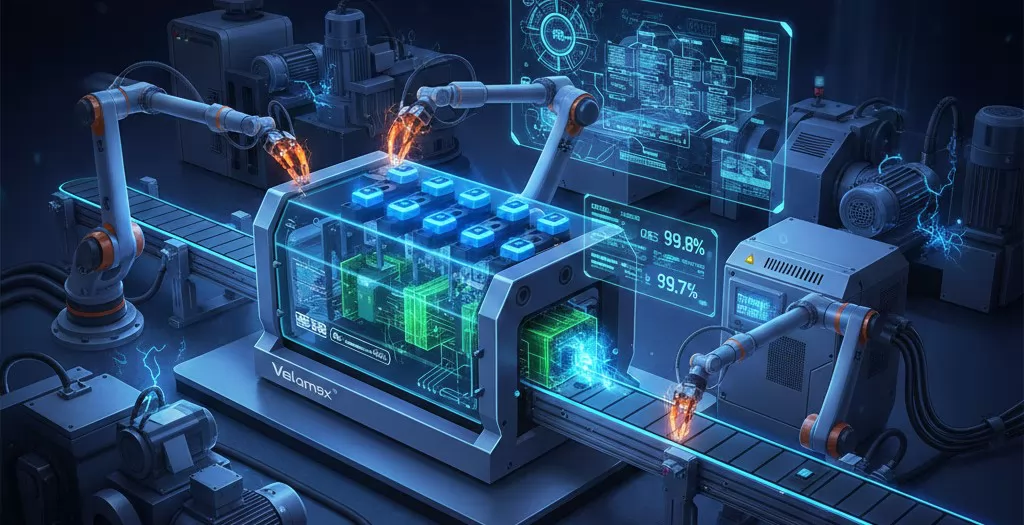

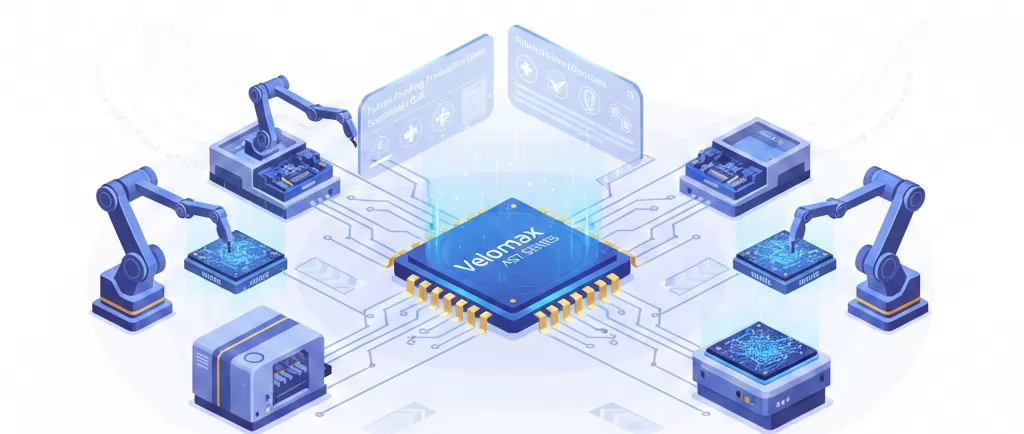

In a modern "Lights-Out" manufacturing environment, a programmer is rarely a standalone unit. It must integrate seamlessly into complex robotic cells. The FPGA architecture is the secret behind the massive scalability of the Velomax AST Series. Unlike MCU-based systems that struggle to maintain performance as more sockets are added, the modular nature of FPGA logic allows for linear scaling. Each programming site can be governed by its own dedicated logic slice, ensuring that an 8-socket system is just as fast and stable as a single-socket station.

Integration with automation requires more than just speed; it requires sophisticated communication with PLCs (Programmable Logic Controllers) and MES (Manufacturing Execution Systems). Our FPGA-driven systems provide ultra-low-latency handshaking signals that allow the robotic pick-and-place arms to synchronize perfectly with the programming cycle. This eliminates the "waiting time" that often plagues less advanced systems.

By choosing the AST Series, manufacturers are not just buying a programmer; they are investing in a next-gen programming system designed for the demands of the AI-driven digital transformation era. Velomax ensures that the transition from manual lab work to fully automated mass production is effortless and efficient.

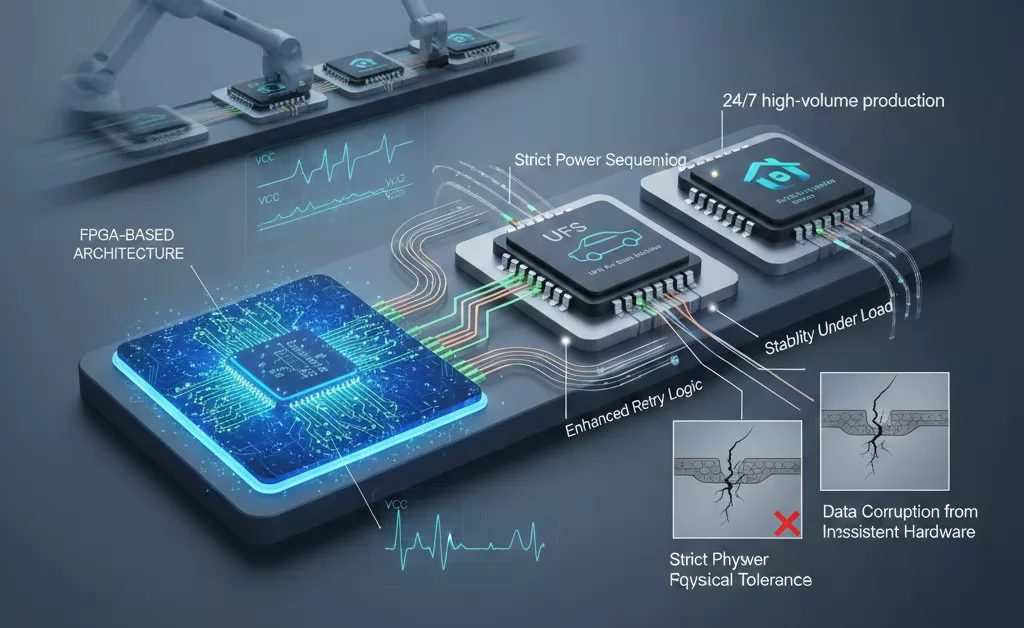

In industries such as automotive manufacturing and AI infrastructure, the cost of a single IC failure can be catastrophic. UFS for electric vehicles and eMMC for smart home hubs require a programming process that guarantees data retention and reliability over years of operation. An FPGA-based architecture contributes to this reliability by providing a controlled, predictable environment that minimizes "electrical stress" on the flash cells during the write cycle.

Because Velomax systems utilize FPGA logic to manage power sequencing and voltage levels at the millivolt level, we ensure that every chip is programmed within its optimal physical tolerances. This level of precision prevents the degradation of the floating gate in NAND flash, which is a common cause of data corruption in chips programmed by low-cost, inconsistent hardware.

With 10 years of hardware mastery, Velomax understands that for automotive OEMs, "good enough" is not an option. Our FPGA architecture is the foundation for a zero-defect strategy, providing the stability and precision required for the most demanding electric vehicle and industrial electronic equipment applications.

The rapid acceleration of the AI era and the global digital transformation mean that the ICs of tomorrow will be denser, faster, and more complex than those of today. For manufacturers, the goal is to build a production line that does not require constant reinvestment in core infrastructure. An FPGA-based architecture is the ultimate tool for future-proofing, acting as a bridge between current capabilities and future requirements.

By choosing a system like the Velomax AST Series, companies are investing in a platform that is inherently adaptable. As new standards for SPI Flash, UFS, or specialized automotive MCUs emerge, the "intelligence" of the programmer can be re-mapped at the gate level. This eliminates the traditional trade-off between choosing a specialized (but rigid) tool and a flexible (but slow) one. With FPGA logic, you get the speed of dedicated hardware with the flexibility of software.

At Velomax, we believe that programming should be as effortless and essential as the air around us. By leveraging our 20 years of software innovation and a decade of hardware expertise, we provide the tools that allow engineers to focus on innovation rather than troubleshooting their production line. The future of programming is high-speed, automated, and fundamentally driven by FPGA excellence.

Velomax – A Brand Built on Expertise With over 10 years of hardware design and 20 years of software development experience, Velomax elevates user-driven innovation into a new era of aero-speed performance. In the post-pandemic era, AI advancements have been pivotal in reshaping society and accelerating global digital transformation. Velomax specializes in high-speed programmers for high-density devices, including UFS for electric vehicles, eMMC for smart home appliances, and SPI Flash for electronic equipment.

The AST Series represents the pinnacle of automation—a next-gen programming system powered by the AeroSpeed Series with advanced FPGA architecture. Designed for ultra-fast, flawless execution, it delivers unmatched speed and precision, making programming an integrated, effortless part of your production workflow.

Technological Leadership: Velomax Semiconductor possesses advanced programming technologies, supporting the latest memory devices and microcontrollers with hardware-level precision.

High-Precision Equipment: We provide robust, reliable programming equipment that ensures the high stability and reliability required for industrial and OEM applications.

Professional Team & Support: With a team of experienced technicians and strategically located global teams, we provide unwavering support and proactive assistance locally.

Continuous Innovation: We push the boundaries of technology through continuous R&D investment to ensure our customers stay ahead in the AI and EV markets.

Discover this amazing content and share it with your network!

Your Name*

Your Email*

*We respect your confidentiality and all information are protected.